When 3D printing became mainstream, people got excited about its possible applications in fields like medicine. In just a few years, professionals have figured out how to create medical equipment, prosthetics, and even organs out of a 3D printer.

While some of these innovations may be far from feasible and complete, it’s still thrilling to know that humans will benefit from them in the future. Get to know how 3D printing works and how it’s leading the charge in medicinal innovations.

The 3D Printing Process

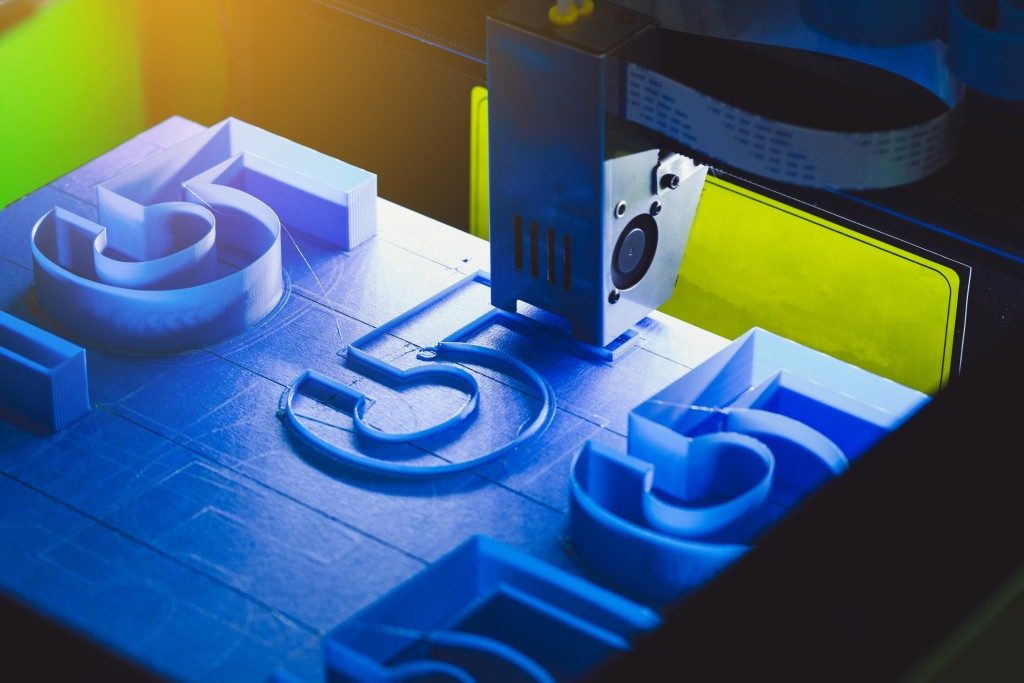

3D Printing was initially created to make product prototypes faster and cheaper. Back then, you had to spend days and weeks carving prototypes out of wood or sticking together pieces of plastic to make a decent prototype. Now, you can create a perfectly accurate one in just a few hours with a 3D printer. However, it has extended beyond making quick drafts of products, to manufacturing the actual items themselves. ;

The process of 3D printing starts on a personal computer. An expert artist will design a 3-dimensional object on computer-aided design (CAD) software, like the ever-popular Autodesk. It’s then sent to the 3D printer itself, which meticulously creates the model from the bottom up, one layer at a time. These printers often use molten plastic or powder to create the models, and they’re held together by a special adhesive.

Medical Applications

3D printing in medicine mostly uses plastic, but experts are looking into creating organic inks from biomaterials. These are made with organic tissue, which means that they can accept and transmit nutrient. And scientists are looking to make real organs out of them. Here’s what they’re making so far.

- Orthodontics — Creating dental materials like retainers and aligners used to be very costly and came with the risk of human error. Now, digital dental laboratories can create 3D-printed aligners using digital scans of a patient’s teeth. This cuts out labor costs and eliminates the need to develop a physical mold of the customer’s mouth.

- Prosthetics — Traditional prosthetic often cost between $1,500 to $8,000 to make, as they’re made with expensive materials like carbon fiber and metals like titanium to ensure that they’re sturdy. Plus, there’s also the labor that goes into creating the customized artificial limb. Now, people can get personalized prosthetics foras low as $4 through 3D printing. Options range from stationary limbs to advanced, digitally-controlled arms and gauntlets.

- Organs — Researchers have long-pondered the possibility of creating artificial organs. However, they didn’t believe it was feasible until the 3D printer came along. Recently, scientists at Rice’s Brown School of Engineering created a lung-like model out of a 3D printer and bio-materials. They made artificial versions of lung tissues and passageways for blood and air. While this is still not ready to be transplanted into a living being, it’s a step forward for patients who desperately need organ donations.

3D printing continues to make strides in different scientific fields. But nothing compares to the great changes it’s making in the field of medicine. Some 3D-printed innovations have already kicked into high gear with products like customized retainers already hitting the market. While others still need a lot more research before the public uses them. Either way, the more affordable medical materials and equipment that comes from 3D printing will always be worth the wait.